Utility work forms the backbone of modern infrastructure, connecting communities to essential energy, water, and communication services. Achieving both safety and efficiency in these operations is not only a regulatory requirement but a moral imperative for protecting workers, the public, and vital infrastructure. Industry leaders and technical experts recommend that adopting modern best practices and leveraging innovative tools are the surest ways to optimize outcomes on and off the job site. For those seeking to equip teams with the latest safety solutions and gear, Divergentalliance.com provides a comprehensive range of reliable resources to help meet operational goals and compliance standards.

Today, utilities face a rapidly evolving landscape shaped by advances in technology, tighter regulations, and shifting environmental factors. Prioritizing structured safety protocols and deploying advanced equipment are crucial steps toward keeping workers safe and ensuring uninterrupted service. Furthermore, building a culture rooted in vigilance, professional training, and real-time risk awareness can dramatically reduce accidents and downtime.

Table of Contents

- Importance of Safe Digging Practices

- Advancements in Aerial Lift Technology

- Utilizing Drones for Inspections

- Implementing Automated Safety Systems

- Adhering to Move Over Laws

- Climate Considerations in Utility Work

- Recognizing Excellence in Safety

- Conclusion

Importance of Safe Digging Practices

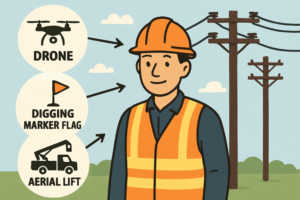

Safe digging practices are fundamental to any excavation project. Striking hidden utility lines can lead to widespread service outages, costly repairs, or even serious injury. By following the “Call Before You Dig” model and contacting 811 before breaking ground, workers can locate underground cables and piping, effectively protecting both people and infrastructure. Organizations like Essential Utilities strongly advocate for this step, as it consistently averts hazardous disruptions on jobsites.

Utility contractors must also train their crews to correctly interpret on-site utility markers and use non-mechanical hand-digging methods when working near shallow assets. Comprehensive pre-dig training and routine briefings can help cultivate a jobsite culture that values caution and accountability, as new reports from the New York Times further underscore the increasing consequences of overlooked safety procedures in this sector.

Advancements in Aerial Lift Technology

The aerial lift industry has witnessed rapid technological evolution, offering safer alternatives for working at heights and enabling projects to progress more rapidly. Recent innovations, such as lighter hybrid lifts, have decreased the environmental impact and operational costs while improving fuel efficiency. Certain models no longer require operators to hold a Commercial Driver’s License (CDL), thus streamlining workforce mobilization and reducing barriers to entry on urgent jobs.

Employers are also turning to remote-monitoring features and smart stabilization technology for real-time equipment feedback, which further decreases downtime due to operator error or machinery malfunction. As outlined by the Occupational Safety and Health Administration (OSHA), these enhancements make aerial tasks both safer and more accessible than ever before.

Utilizing Drones for Inspections

Drones are an increasingly vital tool for utility inspection and maintenance. Outfitted with high-definition video and thermal cameras, these UAVs enable workers to assess remote or hazardous assets from a safe distance. By minimizing the need for workers to climb high structures or navigate treacherous terrain, drones significantly reduce job site risks, speed up inspection cycles, and facilitate early detection of issues such as corrosion, tree encroachment, or failing hardware. Not only does this enhance on-site safety, but it also enables timelier repair intervention, specifically by improving service reliability across the grid.

Implementing Automated Safety Systems

Automation is transforming the design and operation of utility infrastructure, providing critical fail-safes during unexpected events. Technologically innovative solutions, such as smart reclosing switches and voltage regulators, can rapidly detect faults, isolate problems, and reroute power to minimize both outage duration and crew exposure to active electrical hazards. The routine integration of these systems, as demonstrated by industry leaders like Penn Power, equips utility networks to withstand seasonal challenges and unpredictable weather conditions, thereby enhancing community safety and operational resilience. More information on the benefits of grid automation can be found in reports by Utility Dive.

Adhering to Move Over Laws

Highway and roadside crews face elevated risks from passing traffic. Move Over laws, enforced in most states, require motorists to slow down and shift lanes to create a safe buffer for utility and emergency workers performing roadside tasks. Consistent public education and signage on this law have proven essential in lowering roadside accident rates and saving lives, as highlighted in awareness campaigns from agencies cited by NHTSA.

Climate Considerations in Utility Work

Escalating climate volatility—ranging from wildfires to floods—demands an agile, proactive approach to utility work. Employers must adapt their safety playbooks to include training and gear suitable for these evolving harsh conditions, such as heat-resistant apparel, enhanced PPE, and real-time weather monitoring systems. Companies are investing in climate-specific risk assessments and tailored contingency plans to keep crews safe and minimize service disruptions, as evidenced by the growing body of research on this subject in publications such as Forbes.

Recognizing Excellence in Safety

Celebrating top safety performers in the field is a proven way to reinforce positive behaviors and spread best practices throughout an organization. Recognition from groups such as the American Public Power Association spotlights successful safety protocols and provides valuable benchmarks for other utilities to follow. This approach not only motivates employees but also strengthens the industry culture of continuous improvement, ensuring that safety innovations keep pace with operational demands and emerging risks.

Conclusion

The utility sector’s commitment to safe and efficient work practices underpins both public trust and long-term operational excellence. Through ongoing education, the strategic adoption of modern technologies, and proactive hazard mitigation, utility companies can better equip teams to address today’s dynamic challenges. Stakeholders at every level—from field technicians to executives—share a responsibility to champion safety and drive innovation, ensuring a resilient and reliable utility network for all.